Earth Advantage scores homes based on a worksheet that covers all aspects of construction. Builders earn points by choosing more sustainable construction methods and materials over less sustainable ones. The categories include interior air quality, environmental responsibility, energy efficiency and resource efficiency. The standards Earth Advantage has created target an energy usage of at least 15% less than a home built using the minimum building code. To be Earth Advantage Certified a home must score minimum of 90 points. That qualifies it for a Silver rating. To earn a Gold rating, a score of 120 points, and for a Platinum rating a total of 140 points must be earned. To see the points worksheet Click here.

What is the cost to build a Silver level home? Wh

at about Gold and Platinum. Most builders should be able to attain a Silver level for about $3,800 in labor and materials. Much of it can be done for very little money by considering the Earth Advantage standards in the design process. Things like implementing a waste management plan, reducing house size and taking care to cover the construction site with erosion control materials are examples of low cost solutions.

at about Gold and Platinum. Most builders should be able to attain a Silver level for about $3,800 in labor and materials. Much of it can be done for very little money by considering the Earth Advantage standards in the design process. Things like implementing a waste management plan, reducing house size and taking care to cover the construction site with erosion control materials are examples of low cost solutions.At Miranda Homes we choose to build to a minimum of a Gold level certification. Reaching this level takes more planning and some better material choices. Some of how we reach a Gold level is by using Insulated Concrete Forms for our foundations and Spray Foam Insulation to seal the home against weather. We also use engineered steel studs, advanced framing systems, a home-run plumbing distribution system and an air management system to maximize energy usage and improve the quality of the interior air. We include a conditioned crawl space, rigid foam exterior insulation, a heat pump and run all heating ducts within conditioned space. The additional expense for these items and the other quality, energy efficient products we use comes to about $14,000 over a code built home.

Platinum level certification is the highest award Earth Advantage offers and Miranda Homes will build to this level based on customer requests. To reach Platinum level Miranda Homes includes all of the items used to reach Gold level certification as well as additional landscape planning. The location of the property and its proximity to shopping and public transit must also be considered. To reach this level adds approximately $18,000 in cost over a code built home.

At Miranda Homes we work hard to offset these extra costs through efficiencies in engineering, purchasing and processes.

But we don't do all of this for the certificate. We take these steps to give our customers homes that:

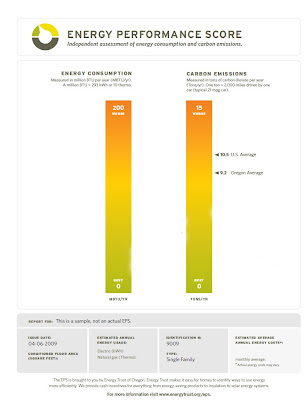

- Reduce carbon footprints - Our Platinum homes produce approximately 5.3 tons less carbon per year than the average home. (Click Here to see what a ton of carbon looks like)

- Reduce utility costs - Our Platinum homes reduce energy bills by an average of 50% over traditional homes.

- Increase the life of the home - All of our homes are estimated by The Office of Sustainable Development to last 100 years longer than a code built home.

- Bring a higher resale value - Earth Advantage homes are proven to shorten time on the market and bring higher prices. (Read a story HERE)

- Reduced waste in landfills - Our recycling program diverts 75% of construction waste to reuse. (approximately 7,500 pounds per home)

To learn more about Earth Advantage and the certification process for new homes click here. For more information about how Miranda Homes reaches Gold and Platinum levels call us at 503-658-4818. We'll be glad to show you our points worksheets.

Mark Mecklem - Miranda Homes